Surface Treatment

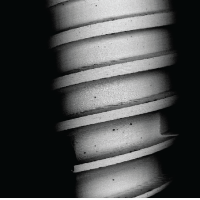

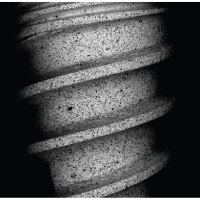

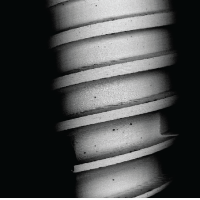

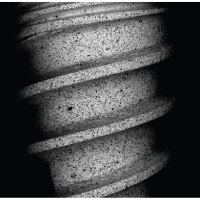

SpiralTech implants all feature a proven RBM Surface.

Applied in a controlled environment, the RBM process uniformly micro-roughens the implant to maximize surface area, bone cell growth and adhesion.

Filler layers that could later form debris or compromise healing are omitted.

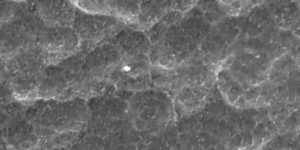

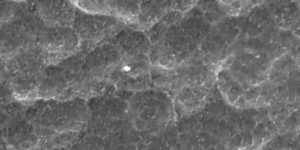

The role of a roughened surface aiding in implant fixation has been well established. Recent concern regarding embedded media from glass beading and grit blasting operations has prompted interest in developing a method to avoid this ontamination. Osteolysis is a primary concern, and has been shown to relate to particulate debris. RBM Bio-Coat has succeeded in developing a process that provides a roughened surface to aid in osseointegration, without the presence of unwanted debris embedded in the implant surface.

SLA is a rough surface technology accomplished by using micro-grit sandblasting. As a result, the titanium implant surface will exhibit a rough morphology and numerous small holes. The next step is to double etching process to the implant surface in order to remove all implpant contamination. The average size roughness is 2.0 ± 5.0 µ for an ideal cell attachment.

Implant after machining and washing is rasnobly clean and mostly free from foreign particles, enabling good conditions for further stages of the surface treatment.

Implant shown after Aluminia Blasting.